The Ultimate Overview to Expanding Life-span: Undercarriage Parts Maintenance Made Easy

The Ultimate Overview to Expanding Life-span: Undercarriage Parts Maintenance Made Easy

Blog Article

Make Best Use Of Performance With Long Lasting Undercarriage Components

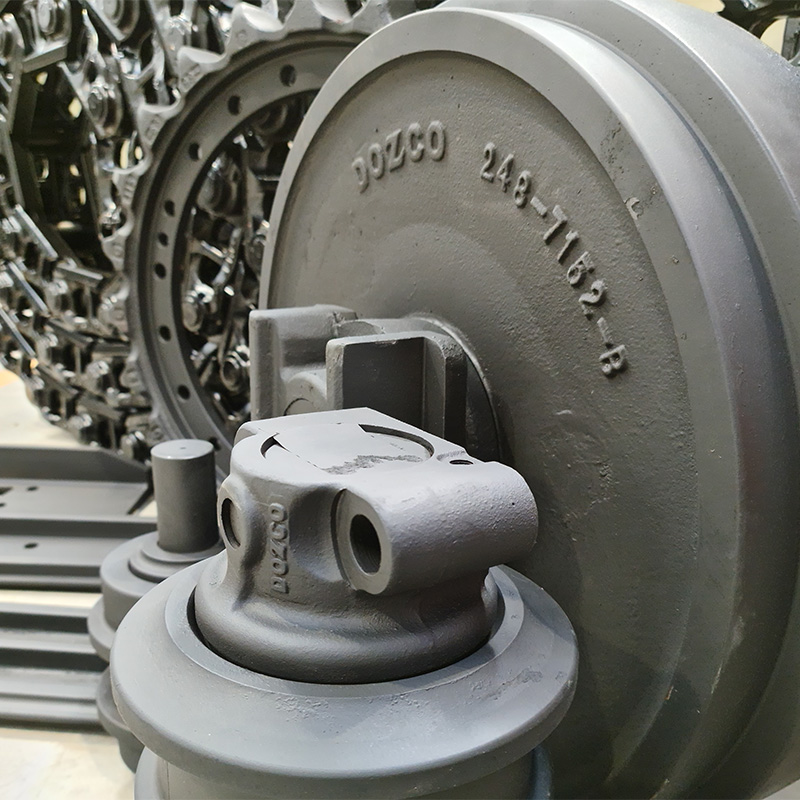

In the realm of heavy machinery and tools, the function of undercarriage components is critical in making sure optimum performance and durability. The effectiveness and efficiency of these components can significantly affect the general operation of machinery, making the option of resilient undercarriage components a critical decision for drivers and supervisors alike.

Advantages of Using Durable Undercarriage Components

Utilizing durable undercarriage components not only enhances the long life of hefty equipment but likewise lessens maintenance expenses considerably. By buying top notch undercarriage components, such as tracks, rollers, gears, and idlers, devices drivers can experience enhanced uptime and improved general efficiency.

Furthermore, the long life of heavy machinery is directly connected to the high quality of its undercarriage components. Long lasting components can stand up to the rigors of demanding applications, making sure that the equipment stays operational for prolonged durations. Therefore, operators can avoid costly downtime and upkeep costs, eventually taking full advantage of the roi for their machinery.

Factors Affecting Undercarriage Resilience

The sturdiness of undercarriage parts in heavy machinery is affected by numerous vital variables that directly impact performance and long life. One of the vital aspects impacting undercarriage toughness is the high quality of materials made use of in production. Top quality products, such as hardened steel, are necessary for holding up against the severe conditions and heavy lots that undercarriage parts go through. Correct upkeep methods also play an important role in determining the life-span of undercarriage components. Routine inspections, lubrication, and prompt substitute of damaged parts can substantially expand the sturdiness of the undercarriage.

Moreover, environmental variables can have a considerable effect on the long life of undercarriage components. Exposure to rough products, extreme temperatures, and extreme working conditions can speed up damage on undercarriage components. For that reason, selecting undercarriage parts that are especially created to withstand these environmental difficulties is important for ensuring longevity.

Furthermore, the style and design of undercarriage components have a direct impact on their toughness. Components that are designed to distribute tons uniformly, lower rubbing, and minimize stress focus are most likely to have a longer life-span - undercarriage parts. By taking into consideration these important elements, equipment operators can maximize the durability and performance of their undercarriage parts

Maintenance Tips for Prolonging Undercarriage Life

Implementing regular upkeep regimens is essential for expanding the life-span of undercarriage parts in hefty machinery. In addition, make certain that the undercarriage is effectively lubed according to manufacturer standards to minimize friction and prevent premature wear.

Another important maintenance pointer is to maintain the undercarriage clean from dust, rocks, and debris. Buildup in the undercarriage can increase wear and corrosion, leading to pricey fixings. Washing the undercarriage after operation in severe conditions is suggested to avoid these problems.

Last but not least, tracking and recording upkeep activities can aid in developing a positive maintenance routine. Keeping thorough records of inspections, replacements, and fixings can give valuable insights into the undercarriage's problem and efficiency with time, helping in predicting and avoiding possible failings. By adhering to these upkeep tips diligently, drivers can substantially increase the toughness and performance of undercarriage components in hefty equipment.

Choosing the Right Undercarriage Elements

Choosing suitable undercarriage parts is crucial for making the most of the efficiency and long life of heavy machinery. When it comes to selecting the appropriate undercarriage parts, there are a number of aspects to take into consideration.

In addition, thinking about the quality and reputation of the supplier is essential. Opting for trustworthy brands known for generating resilient and high-performance undercarriage parts can dramatically impact the general effectiveness and durability of the equipment. In addition, making certain that the elements work with the device version and appropriately mounted is crucial for optimal performance. By meticulously picking the best undercarriage components, devices owners can improve performance, minimize downtime, and extend the lifespan of their heavy equipment.

Instance Researches: Enhanced Performance With Resilient Components

Including resilient undercarriage parts has shown considerable enhancements in machinery efficiency. One situation research entailed a construction official website company that upgraded its excavator's undercarriage components to much more sturdy choices. The firm observed a noteworthy reduction in downtime as a result of undercarriage maintenance, causing increased productivity and price financial savings. The sturdy parts withstood extreme working problems, decreasing deterioration substantially.

In another instance, a mining procedure changed the undercarriage parts of its excavator with high-quality, durable alternatives. This button resulted in an exceptional renovation in the excavator's maneuverability and overall performance. The equipment might browse challenging surfaces a lot more successfully, resulting in improved operational efficiency and lowered gas consumption.

In addition, a logging firm about his invested in durable undercarriage parts for its forestry tools. These case research studies underscore the tangible benefits of using long lasting undercarriage components in maximizing machinery performance and long life.

Conclusion

To conclude, making use of sturdy undercarriage components can substantially improve efficiency and long life of heavy machinery. Elements such as appropriate maintenance and picking the best elements play a vital duty in making the most of undercarriage toughness. By implementing these strategies, services can decrease downtime, increase efficiency, and ultimately conserve on operational prices. Situation researches have shown that purchasing sturdy undercarriage parts can lead to enhanced total efficiency and productivity in different markets.

The efficiency and performance of these components can substantially influence the overall operation of machinery, making the choice of long lasting undercarriage components an essential decision for operators and managers alike.Integrating resilient undercarriage parts has shown significant enhancements in equipment performance. These situation research studies underscore the concrete benefits of using resilient undercarriage parts in enhancing equipment efficiency and longevity.

In final thought, using durable undercarriage parts can significantly boost performance and long life of heavy machinery (undercarriage parts). Situation studies have revealed that spending in long lasting undercarriage parts can lead to boosted overall efficiency and performance in go to this web-site various sectors

Report this page